After the interim government took office, they made significant efforts to eliminate the use of banned polythene bags. While the ban has been largely successful in supermarkets, polythene bags continue to be used in the open market, as before.

Amidst this scenario, several entrepreneurs have stepped forward to produce environmentally friendly bags. However, these innovators, despite setting up factories, are now in a helpless position. They are unable to obtain approval to produce bags made from corn starch. Their efforts have been stalled as they navigate through various bureaucratic channels of the Department of Environment.

Reports suggest that officials from the department are providing various excuses to the entrepreneurs. Investigations reveal that at least three entrepreneurs are interested in producing biodegradable bags made from corn starch, but after three years of trying, none have received the necessary clearance. Among these is Crystal Biotech, based in Rajshahi. Despite three years of persistent effort, the company has yet to receive permission to produce corn starch bags. Similarly, J.K. Polymer from Gopalganj has set up a factory and is conducting trials, but it, too, has not received clearance despite applying over a month ago.

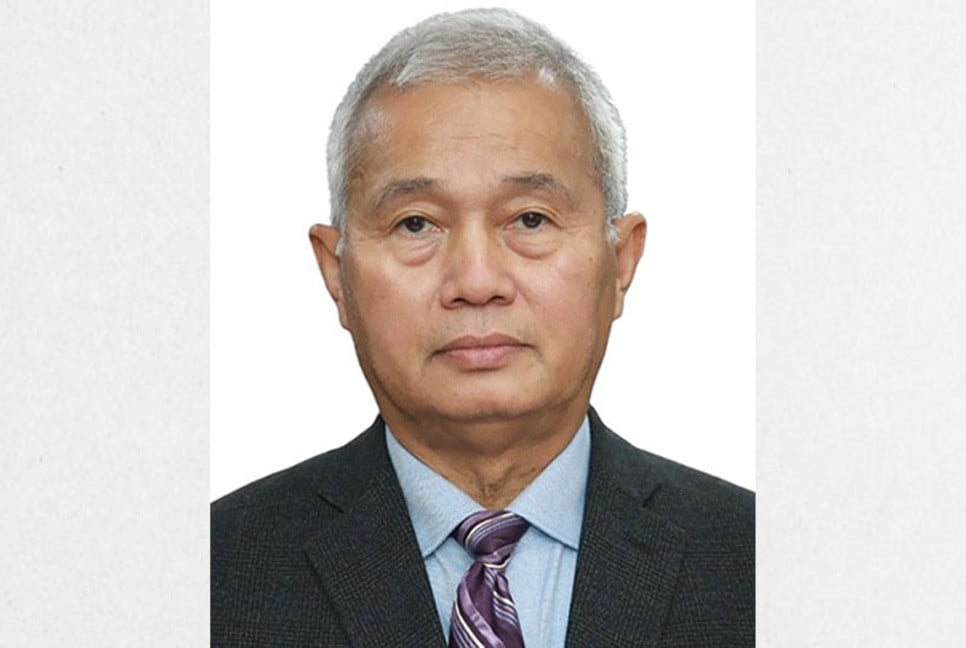

Iftikharul Haque, the proprietor of Crystal Biotech, expressed his frustration, saying, "It's been nearly three years since we applied, but the Department of Environment has not issued us a clearance. They claim our application is in Dhaka, but no clear reason has been provided for the delay. Each time, we hear a different excuse. It could be bureaucratic red tape or something else. I am working for the environment, yet the department responsible for environmental protection is withholding the necessary permission. Our factory emits no waste and falls under the green category. The bags we produce are eco-friendly and decompose within a month without harming the soil. I cannot understand why we are not being approved.”

On the other hand, those making jute bags face another challenge. A jute bag entrepreneur mentioned that there is insufficient supply of jute in the market to meet the demand for bags. The shortage has hindered production. Furthermore, the open market remains largely unaffected by measures to reduce polythene usage, as prices and supply of polythene remain unchanged. Meanwhile, entrepreneurs investing in environmentally friendly bags made from corn starch continue to struggle without the necessary clearances.

In contrast, Chittagong-based Earth Matters Limited has received permission to produce biodegradable bags made from corn starch. These bags are exported as garment packaging to countries in Europe and the USA. However, the company has not been granted approval to sell these bags in the local Bangladeshi market. They have held discussions with environmental adviser Syeda Rizwana Hasan, who has assured them that the feasibility of permitting local marketing of these bags will be reviewed.

Sonali Bag Production in the Shadows

The "Sonali Bag," developed by Bangladeshi scientist Dr. Mubarak Ahmed Khan from jute fiber, remains far from commercialization due to a lack of necessary government funding. Additionally, a policy framework required to transfer this technology to private entrepreneurs has not yet been formulated. As a result, the commercial production of Sonali Bags remains in the dark.

Dr. Mubarak Ahmed Khan stated, “There has been little progress in Sonali Bag production. We have not received any funds from the government, nor have we been able to procure machinery. The government has promised Tk 1 billion this month, but without funds, there is little I can do. I have also suggested transferring the technology to private entrepreneurs under a clear policy framework, as many domestic and international companies are interested. However, this is also yet to happen.”

Bd-pratidin English/ Afia