While learning to fly a helicopter in college, Hector Xu experienced several "nasty" incidents while trying to navigate at night. These intense flights sparked his interest in unmanned aircraft systems, leading him to pursue a doctorate in aerospace engineering at the Massachusetts Institute of Technology. In 2021, he founded Rotor Technologies to develop unmanned helicopters.

Rotor has built two autonomous Sprayhawks and aims to have as many as 20 ready for market next year. The company also is developing helicopters that would carry cargo in disaster zones and to offshore oil rigs. The helicopter could also be used to fight wildfires.

For now, Rotor is focused on the agriculture sector, which has embraced automation with drones but sees unmanned helicopters as a better way to spray larger areas with pesticides and fertilizers.

On Wednesday, Rotor will conduct a public flight test of its Sprayhawk at an agriculture trade show in Texas. Xu revealed that numerous inquiries about using the aircraft for crop dusting made them realize the market potential. The Associated Press reporters were the first outsiders to witness the test flight, during which the Sprayhawk hovered, flew forward, and sprayed the tarmac before landing.

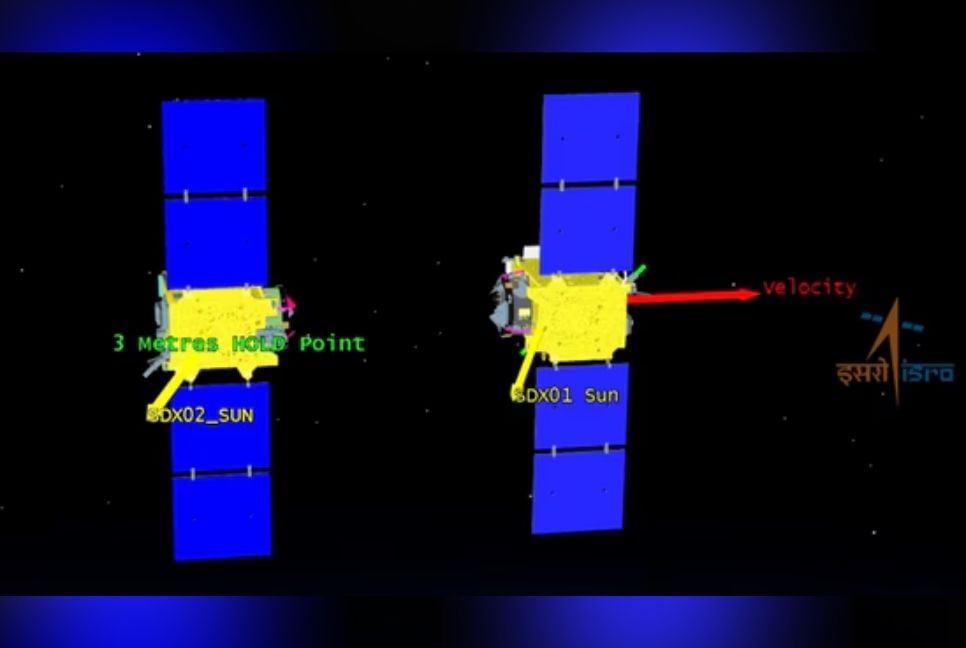

Rotor's nearly $1 million Sprayhawk helicopter is a Robinson R44, but the four seats have been replaced with flight computers and communications systems allowing it be operated remotely. It has five cameras as well as laser-sensing technology and a radar altimeter that make terrain reading more accurate along with GPS and motion sensers.

At Rotor's hangar in Nashua, New Hampshire, Xu highlighted that the technology improves night-time terrain visibility.

A major advantage of automation in agricultural aviation is safety, as crop dusters, flying at 150 mph and just 10 feet off the ground, frequently crash due to collisions with powerlines, towers, and other planes, often caused by outdated planes and pilot fatigue.

A 2014 National Transportation Safety Board report revealed over 800 agricultural accidents between 2001 and 2010, including 81 fatalities. A more recent report from the National Agriculture Aviation Association recorded nearly 640 accidents and 109 deaths since 2014. Dan Martin, a USDA researcher, called it a "very dangerous profession," noting that long hours and exposure to chemicals contribute to the risks.

In recent years, safety concerns and the cheaper cost has led to a proliferation of drones flying above farmers' fields, Martin said, adding that some 10,000 will likely be sold this year alone.

But the size of the drones and their limited battery power means they only can cover a fraction of the area of a plane and helicopters. That is providing an opening for companies building bigger unmanned aircraft like Rotor and another company Pyka.

The California-based Pyka announced in August that it had sold its first autonomous electric aircraft for crop protection to a customer in the United States. Pyka's Pelican Spray, a fixed-wing aircraft, received FAA approval last year to fly commercially for crop protection. The company also sold its Pelican Spray to Dole for use in Honduras and to the Brazilian company, SLC Agrícola.

Lukas Koch, chief technology officer at Heinen Brothers Agra Services, the company which bought the Pelican Spray in August, has called unmanned aircraft part of a coming “revolution," that will save farmers money and improve safety.

The Kansas-based company operates out of airports from Texas to Illinois. Koch doesn't envision the unmanned aircraft replacing all the the company's dozens of pilots but rather taking over the riskiest jobs.

“The biggest draw is taking the pilot out of the aircraft inside of those most dangerous situations,” Koch said. “There’s still fields that are surrounded by trees on all borders, or you’ve got big, large power lines or other just dangers, wind turbines, things like that. It can be tough to fly around.”

But Koch acknowledges autonomous aviation systems could introduce new dangers to an already chaotic airspace — though that is less of a concern in rural areas with plenty of open space and fewer people.

“Putting more systems into the air that don’t have a pilot inside could introduce new dangers to our current existing pilots and make their life even more dangerous," he said. “If you’ve got this full size helicopter flying beyond the line of sight, how is it going to react when it sees you? What is it going to do? ... That's a giant question mark, one that we take very seriously.”

Companies like Rotor have incorporated built-in in contingencies should something go wrong — its helicopter features a half-dozen communications systems and, for now, a remote pilot in control.

If the ground team loses contact with the helicopter, Rotor has a system which Xu referred to as a big, red button that ensures the engine can be shut off and the helicopter perform a controlled landing. “That means that we’ll never have an aircraft fly away event," he said.

The safety measures will go a long way to helping the company receive what it expects will be FAA regulatory approval to fly its helicopters commercially. Once they have that, the challenge, as Xu sees it, will be scaling up to meet the demand in the United States but also Brazil which has a huge agriculture market but more relaxed regulatory environment.

“I think 2025 will be production hell as Elon Musk calls it,” Xu said. “It’s kind of the difference between building a couple to building tens and hundreds at scale ... These are no longer just like bespoke Rolls-Royces. You want to be stamping these out like you would production automobiles."

Source: abcnews

Bd-pratidin English/ Afia